Wire Pull Handles

Wire Pull Handles are a class of handles manufactured using wire construction. Usually, a wire is bent at both ends and then drilled and tapped. Other forms of production are available, such as casting, which allows for the production of more complex Wire Pull Handles.

- Free samples

- Free Programs

- Free Catalog

Tell us what you think about customizing your Wire Pull Handle

To order Wire Pull Handles, just let us know your requirements. For example, wire diameter, thread size, center distance and bending height. Also what material is used and what is the surface treatment. These are important basic parameters, so feel free to contact us.

All You Need To Know About Wire Pull Handles

We have described above what Wire Pull Handles are, but below we will go into more depth about Wire Pull Handles, such as what materials they are made of, how they are finished, and where they are mainly used. How to determine the detailed dimensions, etc.

Wire Pull Handles are one of the most popular types of products we have ordered for MHANDLES‘s customers. We have a lot of experience in producing them, and some of them are even specified for certain fields.

About Customized Wire Pull Handles

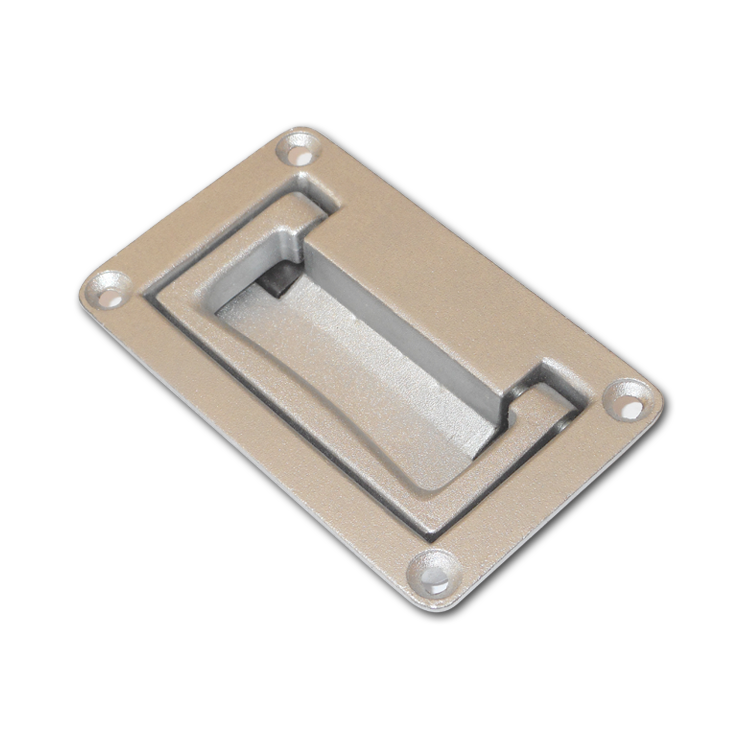

How do I determine the size of Wire Pull Handles?

Wire Pull Handles are relatively simple in construction and we only need to determine a few important dimensions, such as wire diameter, screw size, center distance, and bend height. Knowing these parameters, we are ready to start production.

Bending height size we should pay particular attention to, if the height is too short will affect the reach in. According to our production experience, the minimum height should be set at least 35mm high to be appropriate.

Surface treatment of wire pull handles

Generally speaking, the surface treatment of the wire pull handle depends on the material used. If it is made of iron, the general use of electroplating, painting and other processes. If it is made of stainless steel, the polishing process is generally used. If the material is made of zinc alloy, the process of spraying, anodizing, etc. is generally used.

- If you have a special surface treatment request, you can contact our engineers directly and send your request by clicking the button next to it.

Customer feedback photos

Practical use cases

Wire Pull Handles are mainly used for industrial cabinets, automation equipment, communication cabinets, outdoor camping equipment, etc. Of course, they can also be used in any suitable place according to the customer’s own situation.

A quality box handle must be strong and durable, easy to operate and not hurt your hands, especially for heavy mobile equipment. We will even design the size of the handle according to the size of the hand of people in different countries.

We Leave No Room For Doubt

Experienced in the industry

We have a 20 years’ professional service team focused on the Box Handles. Any questions about Box Handles, our team can answer them for you.

Strong production capacity

Once the samples are confirmed, we will mass produce the goods in the shortest possible time. And we ensure high quality production of products.

With a full range of safety certifications

Our factory has undergone multiple certifications, including ISO, TUV, CE, UL, VDE, RoHS certification.

Outstanding product advantage

Each batch of raw materials has strict inspection and material certification. Sampling and inspection will be conducted before product shipment to ensure the quality of each batch.

FAQs about Wire Pull Handles

How to install the wire pull handle?

The installation of wire pull handles requires knowing the distance between the screw holes. Then drill holes in the panel, it should be noted that the size of the holes should not exceed the diameter of the handle.

Can Box handles be customized in different colors?

Of course, we mainly customize wire pull handles for our customers, including material, surface treatment, structure, function, etc.

What data do I need to provide to order wire pull handles?

You need to know the material, finish, length of the pull, bending height, screw size and other information. Depending on the use of the customer’s equipment these data are easy to obtain.

DO YOU COME WITH MOUNTING SCREWS?

Generally we do not come with mounting screws, as the length of screws required for installation may vary from customer to customer.

What is the maximum and minimum diameter of wire that can be ordered?

Currently we are able to order a maximum diameter of 24mm and a minimum diameter of 4mm, a range that can meet the needs of most customers.

What are the payment options?

We have the following payment methods:

1. Lead Time: 20 days after received 30% deposit

2. Payment: T/T, L/C at sight, Western Union

3. Free samples for one to three pieces, Freight on customers’ side

4. LCL by express, e.g: FEDEX, DHL,UPS,TNT,etc 5. FCL or LCL by ship

- Communication is the key

We look forward to hearing from you!

Function

We need to know what features you need for a customized product. for a preliminary understanding.

Exterior

You can participate in the design of the product and share your ideas with our design engineers.

Material

Determining the material is an important part, and the engineer will confirm it with you in detail.

Environment

Engineers need to know what environment your customized products are used in to determine product materials.